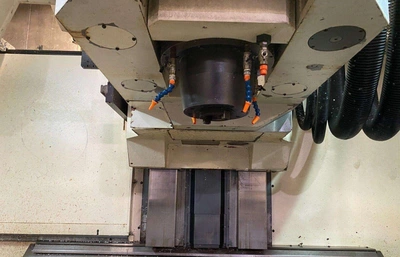

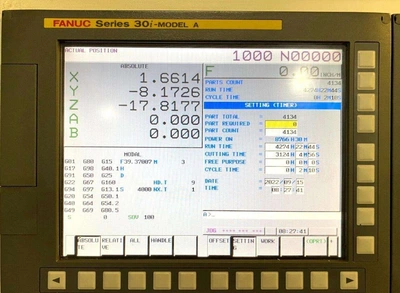

Used 5-axis vertical machining center with Fanuc 30i-MA control. Features a 50 HP spindle motor, 10000 RPM, and 20-tool changer. Equipped with dual chip conveyor, oil chiller, and rigid tapping.

TRAVELS:

X-Axis: 80.0″

Y-Axis: 40.0″

Z-Axis: 30.0″

A-Axis: +/- 35° degrees

B-Axis: +/- 35° degrees

Rapid Traverse Rates: IPM?

Spindle Nose to Table (Min.- Max.): 5.0″ – 39.0″

TABLE:

Length: 82.6″

Width: 41.3″

Number of Std T-Slots: 5

T-Slot Width: 5/8″

Max Weight on Table: lbs ?

SPINDLE:

Articulated 5 Axis

Taper Size: 50

Speed Range: 10000 RPM

Spindle Power: 50 HP

AUTOMATIC TOOL CHANGER:

Capacity: 20

Max Tool Weight: 33 lbs

Max Tool Dia: 5.2″

Max Tool Length: 11.8″

Tool Changing Time: Seconds ?

GENERAL:

Air Required: 100 psi 4 scfm

Power: 220v / 66FLA / 3-Phase

Overall Dimensions: ” x ” x ” High ?

Weight: lbs ?

Fanuc 30i-MA 5 Axis Simultaneous Contouring Control

Articulating Spindle Head (A & B Axis)

Box Way Heavy Construction

50 HP High Torque Spindle Motor

50 Taper 10000 RPM Spindle

20 Automatic tool changer

MPG Control

Rigid Tapping

Spindle Orientation

Telescopic way covers

Oil Chiller Unit

Coolant Tank

Dual Chip Conveyor

We use cookies to improve your experience. Privacy Policy.