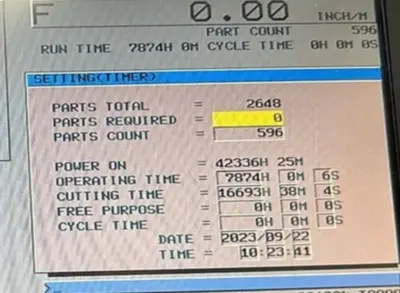

Used Horizontal machining center, equipped with FANUC 16i-MB control, full 4th axis, CoolJet coolant system, Renishaw probing. 80.31" x 51.97" x 53.94" travels. 8,000 RPM spindle. Cutting time: 16,693 hours.

PALLET WIDTH 39.37"

PALLET LENGTH 39.37"

PALLET INDEXING FULL 4TH

NUMBER OF PALLETS 2

MAX WORKPIECE WEIGHT 6,600 lb

X-AXIS TRAVEL 80.31"

Y-AXIS TRAVEL 51.97"

Z-AXIS TRAVEL 53.94"

SPINDLE SPEED 8,000 RPM

SPINDLE MOTOR 40 hp

SPINDLE TAPER BT 50

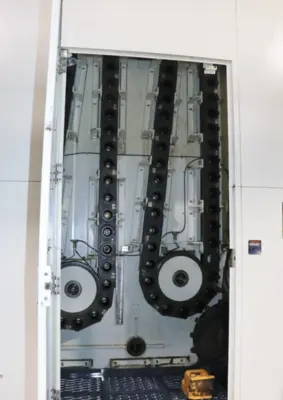

TOOL POSITIONS (ATC) 150

RAPID TRAVERSE RATE 1,417 in/min.

CUTTING FEEDRATE 1,417 in/min.

Dimensions 420” x 210”

FANUC 16i-MB CONTROL

897 FOOT-POUNDS OF TORQUE

HIGH-PRESSURE THROUGH-SPINDLE COOLANT (1,000 PSI)

COOLJET HIGH-PRESSURE COOLANT SYSTEM

FULL 4TH AXIS PALLET CONTOURING

RENISHAW PROBING SYSTEM

150 TOOL POSITIONS

CHIP CONVEYOR

GEARBOX (4-STEP, GEAR DRIVEN)

BOX WAY

LINEAR SCALE FEEDBACK (ALL AXES)

TWIN BALL SCREWS & TWIN SERVO MOTORS

AI NANO HIGH PRECISION CONTOUR CONTROL (500 BLOCK LOOK AHEAD)

TOOL RETRACT & RECOVER

PROGRAM RESTART

APPROX (70) BT50 TOOL HOLDERS

(2) HEAVY DUTY FIXED CUSTOM ENTRY PLATFORMS WITH HANDRAILS

** AS OF OCTOBER 2024, CUTTING TIME - 16,693 HOURS

** MACHINE CUT PRIMARILY ALUMINUM & STAINLESS

We use cookies to improve your experience. Privacy Policy.